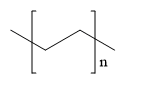

Polyethylene CAS#9002-88-4

CAS Number: 9002-88-4

Chemical Formula: (C2H4)n

Synonyms:

petrothene

pep211

Polyethylene

MOQ (Minimum Order Quantity): 1 FCL (Full Container Load)

Appearance: White to off-white Powder

Polyethylene CAS#9002-88-4

Polyethylene is a flexible waxy translucentpolyalkene thermoplastic made in avariety of ways producing a polymerof varying characteristics. In the ICIprocess, ethene containing a trace of oxygen is subjected to a pressure inexcess of 1500 atmospheres and atemperature of 200°C. Low-densitypolyethene (r.d. 0.92) has a formulaweight between 50 000 and 300 000,softening at a temperature around110°C, while the high-density polythene(r.d. 0.945–0.96) has a formulaweight up to 3 000 000, softeningaround 130°C. The low-density polymeris less crystalline, being more atactic.Polyethene is used as aninsulator; it is acid resistant and iseasily moulded and blown.

| Polyethylene Chemical Properties |

| Melting point | 92 °C |

| Boiling point | 48-110 °C(Press: 9 Torr) |

| density | 0.962 g/mL at 25 °C |

| refractive index | 1.51 |

| Fp | 270 °C |

| storage temp. | -20°C |

| form | powder |

| color | White |

| Specific Gravity | 0.95 |

| biological source | rabbit |

| Water Solubility | Soluble in acetone and benzene. Insoluble in water. |

| Merck | 14,7567 |

| Dielectric constant | 2.2(Ambient) |

| Stability: | Stable, but breaks down slowly in uv light or sunlight. Incompatible with halogens, strong oxidizing agents, benzene, petroleum ether, aromatic and chlorinated hydrocarbons, lubricating oils. |

| Surface tension | 35.7mN/m at 20°C |

| NIST Chemistry Reference | Polyethylene(9002-88-4) |

| IARC | 3 (Vol. 19, Sup 7) 1987 |

| EPA Substance Registry System | Polyethylene (9002-88-4) |

| Safety Information |

| Safety Statements | 22-24/25 |

| WGK Germany | 3 |

| RTECS | TQ3325000 |

| TSCA | Yes |

| HS Code | 39041090 |

| Hazardous Substances Data | 9002-88-4(Hazardous Substances Data) |

Product Application of Polyethylene CAS#9002-88-4

Polyethylene (PE) is a thermoplastic polymer consisting of long hydrocarbon chains. PE is used in a number of applications including flexible film packaging produced by the blown film process. Polyethylene is used to regulate viscosity, suspension properties, and general stability in cosmetic formulations. Typical applications included specialty injection molded parts, in these fields Polyethylene has a wide range of uses:

Injection and blow molded toys, housewares and lids.

Injection molded car seats, mower parts and pails.

Injection molded, thin-walled containers and housewares.

Hot melt coating for paper, additive in cast moldings, candles, oil-based inks and hot melt adhesives.

Factory and Equipment Show

Fast delivery time

Inventory 2-3 working days New production 7-10 working days