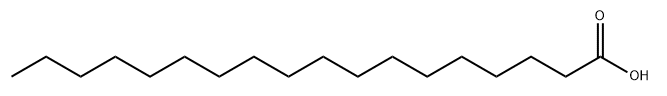

Stearic acid CAS#57-11-4

CAS Number: 57-11-4

Chemical Formula: C18H36O2

Synonyms:

MOQ (Minimum Order Quantity): 1 FCL (Full Container Load)

Appearance: White Powder

Stearic acid CAS#57-11-4

Stearic acid is one of several major long-chain fatty acids comprising oils and fats. It is presented in animal fats, oil and some kinds of vegetable oils as wellin the form of glycerides. These oils, after hydrolysis, produce the stearic acid.

Stearic acid is a fatty acid widely existing in nature and has the general chemical properties of carboxylic acids. Almost all kinds of fat and oil contain certain amount of stearic acid with the content in the animal fats being relative high. For example, the content in the butter can reach up to 24% while the content in vegetable oil is relative low with the value in tea oil being 0.8% and the oil in palm being 6%. However, the content in cocoa can reach as high as 34%.

There are two major approaches for industrial production of stearic acid, namely fractionation and compression method. Add decomposition agent to the hydrogenated oil, and then hydrolyze to give the crude fatty acid, further go through washing with water, distillation, bleaching to obtain the finished products with glycerol as the byproduct.

Most domestic manufacturers use animal fat for production. Some kinds of production technology will result in the incompletion of the distillation of fatty acid which produce stimulating odor at the time of the plastic processing and high temperatures. Although these odor is of no toxic but they will have certain effect on the working conditions and the natural environment. Most imported form of stearic acid takes vegetable oil as the raw materials, the production processes are more advanced; the produced stearic acid is of stable performance, good lubrication property and less odor in the application.

Stearic acid is mainly used for the production of stearates such as sodium stearate, magnesium stearate, calcium stearate, lead stearate, aluminum stearate, cadmium stearate, iron stearate, and potassium stearate. The sodium or potassium salt of stearic acid is the component of soap. Although sodium stearate has a less decontamination ability than sodium palmitate, but its presence may increase the hardness of soap.

Take butter as raw material, go through sulfuric acid or pressurized method for decomposition. The free fatty acids was first subject to water pressure method for removing the palmitic acid and oleic acid at 30~40 ℃, and then dissolved in ethanol, followed by addition of barium acetate or magnesium acetate which precipitates stearate. Then further add dilute sulfuric acid to get the free stearate acid, filter and take it, and re-crystallize in ethanol to obtain the pure stearic acid.

| Stearic acid Chemical Properties |

| Melting point | 67-72 °C (lit.) |

| Boiling point | 361 °C (lit.) |

| bulk density | 400-500kg/m3 |

| density | 0.845 g/cm3 |

| vapor pressure | 1 mm Hg ( 173.7 °C) |

| refractive index | 1.4299 |

| FEMA | 3035 | STEARIC ACID |

| Fp | >230 °F |

| storage temp. | Store below +30°C. |

| solubility | Practically insoluble in water, soluble in ethanol (96 per cent) and in light petroleum (bp: 50-70 °C). |

| pka | pKa 5.75±0.00(H2O t = 35) (Uncertain) |

| form | powder |

| color | White |

| Specific Gravity | 0.84 (80℃) |

| Odor | odorless mild fatty |

| Odor Type | odorless |

| biological source | palm oil |

| Water Solubility | 0.1-1 g/100 mL at 23 ºC |

| Merck | 14,8804 |

| JECFA Number | 116 |

| BRN | 608585 |

| Dielectric constant | 2.3(22℃) |

| Exposure limits | ACGIH: TWA 10 mg/m3; TWA 3 mg/m3 |

| Cosmetics Ingredients Functions | EMULSION STABILISING SURFACTANT - CLEANSING REFATTING CLEANSING SURFACTANT - EMULSIFYING FRAGRANCE |

| InChIKey | QIQXTHQIDYTFRH-UHFFFAOYSA-N |

| LogP | 8.22 |

| CAS DataBase Reference | 57-11-4(CAS DataBase Reference) |

| NIST Chemistry Reference | Octadecanoic acid(57-11-4) |

| EPA Substance Registry System | Stearic acid (57-11-4) |

| Safety Information |

| Hazard Codes | Xi,F |

| Risk Statements | 38-36/37/38-11 |

| Safety Statements | 37/39-26-16 |

| WGK Germany | 3 |

| RTECS | WI2800000 |

| Autoignition Temperature | 395 °C |

| TSCA | Yes |

| HS Code | 38231100 |

| Hazardous Substances Data | 57-11-4(Hazardous Substances Data) |

| Toxicity | LD50 i.v. in mice, rats: 23±0.7, 21.5±1.8 mg/kg, L. Or, A. Wretlind, Acta Pharmacol. Toxicol. 18, 141 (1961) |

Product Application of Stearic acid CAS#57-11-4

Stearic acid is widely used in cosmetics, plastics plasticizers, mold release agents, stabilizers, surfactants, rubber vulcanization accelerator, waterproof agent, polishing agent, metal soap, metal mineral flotation agents, softeners and pharmaceuticals as well as other organic chemicals. Stearic acid can also be used as the solvents of oil-soluble paint, crayons lubrication agent, stencil lighting agent and the emulsifier of stearic acid glyceride.

Stearic acid can also be widely used in the manufacturing of PVC pipe, sheet material, profiles and film and is the PVC heat stabilizers with good lubricity and excellent stability against light and heat. In the application of polyvinyl chloride pipe, stearic acid helps prevent the "coke" during the processing and is effective heat stabilizer during PVC film processing while also preventing the discoloration of the finished film discoloration caused by exposure.

Stearic acid has become the additive for lubrication, plasticization and stabilization of the filled masterbatch. Stearic acid can effectively improve the coating activating effect of inorganic powder and increase the flow rate of materials. When there is demand for a large flow rate of the melt for material with inorganic powder accounting for the most part, an appropriate increase in the content of stearic acid can significantly increase the melt flow rate of material. However, the amount of stearic acid used in filled masterbatch also have threshold with its amount being controlled in about 1% of the total mass. If the added amount is over-excessive, it will not only cause the decrease of the quality and the performance of plastic products but also generate sticky substance in the die lip location of the manufacturing equipment of the plastic products, affecting the production efficiency and product quality.

The mono-or multi-alcohol ester of stearic acid can be used as cosmetics, nonionic surfactants and plasticizers. Its alkali metal salt can be dissolved in water and is a major component of soap. Other kinds of salts can be used as waterproofing agents, lubricants, bactericides, coating additives and PVC stabilizers.

Factory and Equipment Show

Fast delivery time

Inventory 2-3 working days New production 7-10 working days