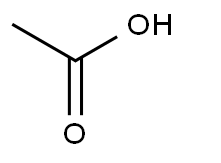

Bio-Based Acetic Acid Achieves 10,000-Ton Industrial Breakthrough, Gains ISCC PLUS Certification, Offering New Low-Carbon Feedstock Option for PTA and Vinyl Acetate Chains

Amid the accelerating greening of petrochemical feedstocks, acetic acid, a key C2 platform chemical, has achieved a major industrial breakthrough. Recently, a renewable acetic acid produced via the selective oxidation of bio-ethanol has reached 10,000-ton scale production and obtained International Sustainability & Carbon Certification (ISCC) PLUS. This technology provides the first large-scale, low-carbon alternative for producing bulk chemicals like purified terephthalic acid and vinyl acetate, as well as for high-end applications in food and pharmaceuticals.

1. Technical Milestone: Selective Oxidation and Ultra-Pure Distillation Process

The breakthrough is centered on advances in high-selectivity catalysis and purification:

High-Efficiency Oxidation of Bio-Ethanol

Patented Process: Utilizes a novel molecular sieve-supported palladium-based catalyst to oxidize bio-ethanol from sustainable sugarcane or corn into acetic acid with high selectivity at moderate temperatures (≤150°C). Compared to the traditional methanol carbonylation route, this technology completely avoids toxic catalyst systems like carbon monoxide and methyl iodide, achieving reaction selectivity above 99% with minimal by-products.

Low-Carbon Feedstock: Enables a closed carbon loop from crop photosynthesis to the final product.

Azeotropic Distillation and Ultra-Low Impurity Control

Reaction and distillation are coupled to occur simultaneously, reducing energy consumption by approximately 25%. Multi-effect azeotropic distillation stabilizes final acetic acid concentration at ≥99.8%, with key impurity formic acid strictly controlled at ≤100 ppm and heavy metal impurities below 0.1 ppm, meeting the highest standards for pharmaceutical and food additive (e.g., GB 1903) use.

2. Sustainability Certifications and Carbon Footprint Advantage

The environmental benefits of this bio-based acetic acid are quantifiably certified:

| Certification System | Core Achievement & Standard |

|---|---|

| ISCC PLUS | Achieves full mass balance traceability from agricultural feedstock (sugarcane/corn) to ethanol and finally to acetic acid, ensuring feedstock sustainability. |

| Carbon Footprint Verification | Verified "Cradle-to-Gate" product carbon footprint is 1.2 kg CO₂eq/kg, representing a reduction of over 40% compared to conventional fossil-based acetic acid (industry average ~2.1 kg CO₂eq/kg). |

| EU Renewable Energy Directive | Complies with RED II requirements for renewable chemicals. Its downstream products (e.g., bio-based PTA) can help end brands reduce Scope 3 emissions. |

3. Industry Impact: Reshaping the Green Starting Point for PTA and VAM Value Chains

As a foundational platform molecule, renewable acetic acid has far-reaching downstream implications:

For the PTA Industry: Acetic acid is a core auxiliary in PTA production. Using renewable acetic acid can reduce the carbon footprint of each ton of PTA by 15-20%. This provides a key solution for polyester fiber and bottle chip manufacturers facing regulations like the EU's Carbon Border Adjustment Mechanism.

For the Vinyl Acetate Industry: Bio-based VAM and its downstream products (polyvinyl alcohol, EVA resins) gain "green credentials," creating differentiated competitiveness in high-end adhesives, green coatings, and biodegradable materials.

Upgrading Traditional Applications: In food and pharmaceuticals, its dual attributes of "bio-based" and "ultra-low impurities" meet the growing market demand for safer, more sustainable additives.

Downstream Benefit Assessment: Although current production costs carry a 20-30% green premium over conventional acetic acid, its overall economic viability is emerging under the drivers of mandatory carbon pricing or brand green procurement policies. For leading consumer brands with carbon neutrality commitments, this premium is acceptable.

4. Corporate Collaboration Case and Strategic Procurement

A global leading polyester producer has signed a long-term offtake agreement, planning to partially blend renewable acetic acid at its European PTA plant. Its sustainability report notes:

"Introducing bio-based acetic acid is a key pathway to achieving our 2030 carbon reduction goals. Preliminary assessment shows that replacing just 30% of acetic acid usage can reduce the annual carbon emissions of that PTA line by approximately 50,000 tonnes. We plan to increase the application ratio of bio-based acetic acid to 50% by 2025."

To cultivate the market, the manufacturer has launched an industry partnership program:

Carbon Credit Linkage: Provides customers with annual offtake exceeding 1,000 tonnes with certified carbon emission reduction documentation for their own ESG reporting.

Application Technical Support: Offers compatibility assessments and transition plans for integrating bio-based acetic acid with existing carbonylation process equipment.

Flexible Logistics: Maintains intermediate storage tanks in Europe (Antwerp) and Asia (Singapore), offering delivery in various specifications including tank trucks and ISO TANKs.

5. Verifiable Data and Safety Assurance

All claims are based on verifiable data and standards:

Product Standards: Purity and impurity testing follows GB/T 1628.1, USP, and Eur. Ph. standards.

Biodegradability: OECD 301F testing shows ultimate biodegradation >99% within 28 days.

Safety Data: Consistent with fossil-based acetic acid, it is a corrosive liquid (GHS classification: Skin Corrosion/Irritation Category 1B), requiring equivalent safety precautions.

The scaled production of this certified bio-based acetic acid marks a substantive step forward in greening the C2 chemical platform. It not only provides a traceable, low-carbon starting point for downstream derivative industries worth hundreds of billions of dollars but also precisely transmits the value of renewable carbon resources to end products through a transparent certification system, accelerating the decarbonization of the entire materials industry.

- Previous : Global Ammonium Chloride Market 2024: Steady Growth Fueled by Agricultural Demand and Industrial Application Expansion

- Next : Food-Grade Anhydrous Calcium Chloride Achieves Low-Carbon Process Mass Production, Gains EFSA & FCC Certification, Offering High-Purity Solutions for Global Cheese, Beverage, and Road Safety Industries