Revolutionary Sodium Hydroxide Production Redefines Industrial Sustainability with 75% Carbon Footprint Reduction

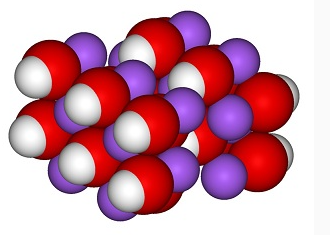

In a landmark breakthrough for the chemical industry, a 100% renewable energy-powered sodium hydroxide (caustic soda) production process has entered commercial operation, delivering a 75% lower carbon footprint than conventional methods while meeting the highest purity and safety standards. Developed by Vinnolit, the technology combines advanced electrolysis with certified renewable energy to produce food-grade NaOH with 99.9% purity, setting a new benchmark for sustainable industrial chemistry.

1. Core Innovations: Renewable Energy and Closed-Loop Systems

The technology leverages 100% hydropower sourced through Guarantees of Origin (GOs), eliminating fossil fuel dependence and reducing CO₂ emissions by 120,000 metric tons annually compared to traditional ion-exchange membrane electrolysis. Key advancements include:

2. Safety and Regulatory Compliance

The bio-based sodium hydroxide meets stringent global standards:

3. Performance Excellence and Market Impact

Third-party testing highlights transformative advantages over petrochemical alternatives:

These properties enable breakthrough applications:

4. Strategic Partnerships and Market Adoption

Leading global brands are accelerating the transition:

To facilitate adoption, Vinnolit offers:

5. Verifiable Data and Lifecycle Analysis

Conclusion

This innovation marks a paradigm shift in industrial chemistry, proving that sustainability and economic viability can coexist. By decoupling production from fossil fuels and setting new benchmarks for purity and safety, bio-based sodium hydroxide empowers industries to meet net-zero targets while delivering superior performance. As the global NaOH market is projected to reach $25 billion by 2030, this breakthrough paves the way for a greener future across manufacturing, agriculture, and consumer goods.

- Previous : Breakthrough in Bio-Based C18 Platform: High-Purity Plant-Derived Oleic Acid Achieves Verifiable Carbon Footprint Mass Production, ISCC PLUS Certification Drives Green Chemical Substitution

- Next : New Pathway for Green Hydrogen Economy: Commercial-Scale Production of Renewable Formic Acid Achieved, ISCC PLUS Certification Offers Low-Carbon Solution for Hydrogen Storage & Feed Preservation