Breakthrough in Bio-Based C18 Platform: High-Purity Plant-Derived Oleic Acid Achieves Verifiable Carbon Footprint Mass Production, ISCC PLUS Certification Drives Green Chemical Substitution

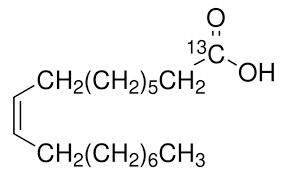

As global manufacturing undergoes a strategic shift toward sustainable feedstocks, a significant industrial advancement has been achieved in the field of oleic acid, a key C18 platform chemical. Recently, a sustainable, plant-derived oleic acid with a purity exceeding 90% has entered scaled production, with its full lifecycle carbon footprint verified and certified under the International Sustainability & Carbon Certification (ISCC) PLUS scheme. This product is positioned to directly replace traditional animal-derived or palm-based oleic acid, offering a high-performance, traceable green raw material solution for the cosmetics, lubricant, polymer, and fine chemical industries.

1. Technical Milestone: Coupled Low-Temperature Fractionation and Molecular Distillation Process

The industrialization's core lies in the green innovation of traditional oleochemical processes:

Selective Hydrolysis and Low-Temperature Fractionation Technology

Patented Process: Employs enzymatic directional hydrolysis to gently release mixed fatty acids from certified sustainable plant oils (e.g., high-oleic sunflower oil), followed by efficient separation of oleic acid from other saturated fatty acids via multi-stage programmed low-temperature crystallization within a narrow 10-15°C range.

Ultra-High Purity: Coupled with short-path molecular distillation for refining, the final product achieves a stable oleic acid (C18:1) content ≥ 90%, while key impurities like linoleic acid (C18:2) are controlled at ≤ 4%. This significantly enhances the product's oxidative stability and batch-to-batch consistency for high-end applications.

Closed-Loop Solvent Management System

The entire separation and refining process utilizes food-grade, eco-friendly solvents within a closed-loop recovery system exceeding 99.5% efficiency, eliminating VOC emissions at the production source.

2. Sustainability Certifications and Full-Chain Traceability

The environmental credentials of this plant-derived oleic acid are built on a transparent, traceable system:

| Certification System | Core Achievement & Standard |

|---|---|

| ISCC PLUS | Achieves complete mass balance traceability from farm to product, ensuring all plant oil feedstocks are sourced from plantations compliant with sustainable agricultural practices, supported by a unique chain of custody certificate. |

| Carbon Footprint Verification | Third-party verified "Cradle-to-Gate" product carbon footprint of 1.5 kg CO₂eq/kg, representing a reduction of over 50% compared to the industry average for conventional mixed-source oleic acid (approx. 3.2 kg CO₂eq/kg). |

| EU Deforestation Regulation (EUDR) | The supply chain fully complies with the due diligence requirements of the latest EU Deforestation Regulation, clearing a major compliance hurdle for market access. |

3. Industry Impact: Performance Optimization and Formulation Upgrade

Third-party comparative test data indicates significant advantages of this high-purity, plant-derived oleic acid in key applications:

| Performance Parameter | This Product (High-Purity Plant) | Conventional Oleic Acid (Animal/Mixed Plant) | Improvement |

|---|---|---|---|

| Iodine Value (g I₂/100g) | 88-90 | 80-90 (high variability) | Higher oxidation stability, lighter color |

| Solidification Point | ≤ 4°C | Typically 10-16°C | Better low-temperature fluidity |

| Conversion Rate in Surfactant Synthesis | 99%+ | Typically 95-98% | Reduced by-products, improved end-product (e.g., AES) quality |

Downstream Benefits: In cosmetic formulations, its high purity and low allergenic potential make it a superior emollient and emulsion stabilizer. In lubricants, its excellent low-temperature performance and biodegradability provide a key ingredient for eco-friendly industrial fluids. Preliminary estimates suggest its higher reaction efficiency could lead to a 3-5% overall cost optimization in producing derivatives like methyl oleate or oleamidopropylamines.

4. Corporate Collaboration Case and Strategic Procurement

A leading international consumer chemicals company has adopted this oleic acid as the starting material for its new green surfactant line. A jointly released brief states:

"Using this sustainable oleic acid increased the natural index (ISO 16128) of our final products, such as cocamidopropyl betaine, by 15 percentage points. More importantly, it provides our brand with a solid, verifiable sustainability narrative. Consequently, we have signed a two-year supply framework agreement with an initial annual offtake of no less than 2,000 tonnes."

To facilitate market adoption, the manufacturer has launched an industry support program:

Technical Collaboration Package: Provides pre-research compatibility data packages for various derivative processes (e.g., ethoxylation, amidation).

Compliance & Certification Support: Offers complete ISCC PLUS chain of custody documents, carbon footprint calculation reports, and REACH registration numbers to support customers' own green claims.

Spot & Future Supply: Maintains bonded tank storage at hubs like Rotterdam and Singapore for flexible, small-batch procurement, while offering cost-lock options for annual contract clients.

5. Verifiable Data and Safety Assurance

All claims are based on publicly verifiable standards and data:

Key Parameter Testing: Analysis of acid value, iodine value, and fatty acid profile follows AOCS Official Methods and USP standards.

Biodegradability: OECD 301F test results show ultimate biodegradation >90% within 28 days.

Comprehensive Safety Data: Classified as a non-hazardous substance per GHS; acute aquatic toxicity (Fish 96h LC50) >100 mg/L.

The mass production of this high-purity, carbon-verifiable, plant-derived oleic acid marks the entry of the monounsaturated fatty acid platform, represented by oleic acid, into a new era of greening and precision. It not only provides downstream industries with a superior-performing raw material option but also translates sustainability commitments into quantifiable, auditable competitive advantages through internationally recognized certification systems, powerfully driving the low-carbon transformation of the entire fine chemical value chain.