Global DMSO Market Enters a New Phase: Surging Demand for High-Purity Pharmaceutical Grade and Green Transformation Driven by China's Capacity Upgrade

Global DMSO Market Enters a New Phase: Surging Demand for High-Purity Pharmaceutical Grade and Green Transformation Driven by China's Capacity Upgrade

Industry Overview: The Modern Transformation of a Universal Solvent

Dimethyl Sulfoxide (DMSO), one of the most important aprotic polar solvents, is accelerating its transformation from traditional industrial applications to high-value-added pharmaceutical and biotech sectors. This sulfur-containing organic compound plays an indispensable role in critical fields such as pharmaceuticals, electronic chemicals, oil and gas, and biological sample preservation due to its exceptional solvent power, superior transdermal absorption properties, and cryoprotective function. Driven by the surging global demand for high-purity pharmaceutical-grade DMSO and breakthroughs in China's eco-friendly production technologies, the DMSO market is facing a significant opportunity for structural upgrading.

1. Core Properties and Application Value: Multifunctionality Beyond a Solvent

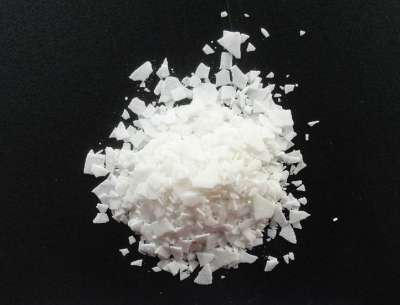

DMSO is a colorless, transparent liquid at room temperature. The sulfur-oxygen double bond in its molecular structure gives it strong polarity, enabling it to dissolve a vast majority of polar and non-polar organic compounds, earning it the title "universal solvent." Key characteristics include:

Solvent Properties: Exceptional dissolving power for a broad spectrum of substances like resins, cellulose, and antibiotics, making it a fundamental solvent in fields such as polymer synthesis and pesticide formulation.

Transdermal Absorption Properties: Highly efficient at carrying drug molecules across biological membranes, making it a crucial penetration enhancer in topical drug formulations and pharmaceutical R&D.

Cryoprotective Properties: Serves as a key protectant in the low-temperature preservation of cells and tissues, widely used in biomedicine and reproductive medicine.

Safety Controversy and Regulation: Despite some toxicity controversies, high-purity pharmaceutical-grade DMSO has been approved by the U.S. FDA for specific drug formulations (e.g., for interstitial cystitis) and is subject to stringent product quality and usage regulations.

2. Market Dynamics: Pharmaceutical-Grade Demand Leads Growth, Asian Capacity Expands Rapidly

The global DMSO market reached approximately $1.25 billion in 2024 and is projected to grow to $1.34 billion in 2025, with a Compound Annual Growth Rate (CAGR) of 7.2%. By 2030, the total market size is expected to exceed $1.8 billion.

Demand Structure Transformation: Demand in the traditional industrial solvent sector remains stable, while the Pharmaceutical and Biotechnology segment is becoming the primary growth engine, currently accounting for 38% of total demand with an annual growth rate exceeding 12%. Electronic chemicals (semiconductor cleaning, photoresist stripping) and veterinary medicine account for 22% and 15%, respectively.

Production Capacity and Trade Landscape: China has become the world's largest DMSO producer, accounting for about 65% of global capacity. China's DMSO exports exceeded 80,000 tons in 2024, primarily destined for Europe, North America, and other Asian regions. Leading domestic companies, through technological upgrades, can now stably produce pharmaceutical-grade products with purity as high as 99.99%.

Price Trends: Influenced by the supply of raw material dimethyl sulfide and environmental costs, industrial-grade DMSO prices fluctuate between $3,000 - $4,000 per ton, while high-purity pharmaceutical-grade products can command prices 3-5 times that of industrial grade.

3. Technological Breakthroughs: Advancements in Green Production and Purity Control

Traditional DMSO production primarily uses the dimethyl sulfide nitric acid oxidation method, which faces issues like high energy consumption and difficult exhaust gas treatment. Current technological breakthroughs focus on:

Optimization of Hydrogen Peroxide Oxidation Process: Using hydrogen peroxide as a green oxidant替代 nitric acid, eliminating nitrogen oxide emissions at the source. The latest catalytic systems have increased conversion rates to over 99.5%, reducing wastewater discharge per ton of product by 90%.

Coupled Continuous Distillation and Molecular Sieve Adsorption Technology: Enables continuous production and effectively removes trace impurities (e.g., dimethyl sulfone, water), allowing product purity to consistently meet USP/EP pharmaceutical-grade standards.

By-product Resource Recovery Technology: Recovers low-concentration DMSO wastewater generated during production through special membrane separation technology, achieving a recovery rate of over 85%, significantly reducing raw material consumption.

4. Application Expansion: From Basic Solvent to Key Material in Cutting-Edge Technology

Pharmaceutical R&D and Production: Demand is growing for its use as a solvent in high-throughput screening for new drug discovery, a protein crystallization reagent, and a cryoprotectant. A stable market exists as a carrier for topical analgesic and anti-inflammatory drugs.

Electronic Chemicals: Demand for ultra-high-purity electronic-grade DMSO (metal ion content <10 ppb), used in photoresist stripping and chip cleaning in semiconductor manufacturing, is growing rapidly with the development of advanced processes.

Veterinary Medicine and Animal Health: Market penetration continues to increase as an efficient transdermal carrier for topical veterinary drugs (e.g., anti-inflammatory, antibacterial preparations).

New Material Synthesis: Serves as a reaction solvent for synthesizing high-performance polymers like polyimides and specialty fibers, supporting the localization of high-end materials.

Biobanking: An internationally recognized standard component of cryopreservation solutions for deep低温 storage of biological samples such as stem cells, organs, and tissues.

5. Future Outlook: Dual Drivers of High-End Specialization and Greening

Growth Drivers:

Biopharmaceutical Innovation: The rapid development of cutting-edge fields like cell therapy and gene therapy will continue to drive demand for high-purity DMSO as a critical process material.

Supply Chain Regionalization: Countries strengthening self-sufficiency in key chemicals creates opportunities for exports of high-specification products from regions like China.

Stricter Environmental Regulations: Tighter global environmental regulations will accelerate the淘汰 of落后产能,推动 the industry's consolidation towards greener production processes.

Main Challenges:

Raw Material Supply Volatility: The stability and price fluctuations of the main raw material, dimethyl sulfide, directly impact industry profitability.

High-End Product Certification Barriers: Entering European and American pharmaceutical markets requires completing stringent DMF (Drug Master File) filings or CEP (Certification of Suitability to the Monographs of the European Pharmacopoeia) certifications, which are lengthy and costly processes.

Safety Perception and Regulation: Continuous scientific communication and standardization of end-use are needed to dispel market misconceptions about product safety.

Industry Insight: The global DMSO industry stands at a crossroads, transitioning from a "bulk chemical solvent" to a "key life science material." China holds advantages in production capacity and cost due to its complete industrial chain and continuously improving process technologies. The future competitive core lies in whether breakthroughs can be made in the stable mass production of ultra-high-purity products, whether an internationally recognized compliance system for pharmaceutical-grade products can be established, and whether customized solutions can be provided around downstream emerging applications. For Chinese enterprises, increasing R&D investment, aligning with international standards, and establishing strategic partnerships with downstream industry leaders will be key to seizing this industrial upgrade opportunity.

- Previous : Industrialization of Bio-based Platform Molecule "Kojic Acid" Accelerates, Poised to Open New Green Chemicals Sector

- Next : Isopropyl Alcohol Industry Approaches an Inflection Point: Surge in Electronic-Grade Demand Drives Value Chain Restructuring, Green Synthesis Processes Reshape Global Landscape