Global Sodium Dodecylbenzene Sulfonate (SDBS) Market Enters Strategic Transition: Green Alternatives Drive Innovation in Detergent Industry

Global Sodium Dodecylbenzene Sulfonate (SDBS) Market Enters Strategic Transition: Green Alternatives Drive Innovation in Detergent Industry

Industry Overview: The Transformation of a Classic Surfactant

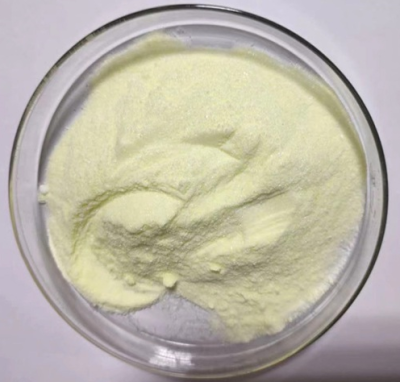

Sodium Dodecylbenzene Sulfonate (SDBS), one of the world's most widely produced anionic surfactants, is undergoing a fundamental transformation driven by global sustainability initiatives and evolving consumer preferences. This cost-effective and highly effective cleaning agent, derived from linear alkylbenzene (LAB), faces both challenges and opportunities as the detergent industry shifts towards eco-friendly formulations. While remaining a cornerstone of household and industrial cleaning products, the SDBS market is now characterized by technological innovation focused on green production processes, enhanced biodegradability, and performance optimization.

1. Core Properties and Market Position: The Workhorse of Cleaning Chemistry

SDBS is characterized by its amphiphilic molecular structure—a hydrophobic dodecylbenzene chain attached to a hydrophilic sulfonate group—which provides excellent detergency, foaming, and emulsifying properties. Its commercial significance stems from several key attributes:

Cost-Effectiveness: Offers superior cleaning performance at a lower production cost compared to many alternative surfactants, making it essential for mass-market detergent formulations.

Hard Water Tolerance: Maintains effective cleaning performance in hard water conditions, a critical requirement for household and industrial applications.

Compatibility: Functions effectively across a wide pH range and demonstrates good compatibility with other surfactants and detergent builders.

Performance Stability: Provides consistent foaming, wetting, and grease-cutting capabilities in various temperature conditions.

Regulatory Status: While facing scrutiny in certain markets due to biodegradation concerns of its branched-chain predecessors, linear SDBS (LAS) meets international biodegradability standards (OECD 301) and remains approved for widespread use.

2. Market Dynamics: Asia-Pacific Dominance Amidst Environmental Pressures

The global SDBS market reached approximately $6.8 billion in 2024 and is projected to grow to $7.2 billion in 2025, with a Compound Annual Growth Rate (CAGR) of 5.9%. By 2030, market size is expected to approach $9.5 billion, with growth primarily driven by developing economies.

Demand Structure: The household detergent sector remains the dominant application, accounting for 65% of global consumption. Industrial & institutional cleaners and personal care products represent 20% and 10% respectively, with agricultural emulsifiers and other specialty applications comprising the remaining 5%.

Production and Trade Landscape: China maintains its position as the world's leading SDBS producer and exporter, accounting for approximately 55% of global capacity. In 2024, China's SDBS and related surfactant exports exceeded 1.2 million tons, primarily destined for Southeast Asia, Africa, and South America. Advanced production facilities in China now achieve biodegradability rates exceeding 95% for linear SDBS products.

Price and Cost Factors: SDBS prices typically range from $1,200 - $1,600 per ton, influenced by benzene and LAB feedstock costs. While facing competition from bio-based alternatives, SDBS maintains a 30-40% cost advantage over many "green" surfactants, securing its position in price-sensitive markets.

3. Technological Advancements: Sustainable Production and Performance Enhancement

Facing environmental regulations and competition, SDBS producers are implementing significant technological improvements:

Advanced Sulfonation Technology: Modern film sulfonation reactors with improved temperature control and SO₃ dosing systems achieve conversion rates above 98.5%, minimizing by-products and reducing energy consumption by 25% compared to traditional processes.

Green Oxidation Process: Implementation of hydrogen peroxide-based oxidation systems for key intermediates reduces chemical oxygen demand (COD) in wastewater by 40% and eliminates sulfur dioxide emissions.

Enhanced Biodegradation Formulations: Development of optimized SDBS blends with specific isomer distributions and chain lengths improves biodegradation rates to >98% within 28 days (OECD 301B), addressing environmental concerns while maintaining performance.

Concentrated Liquid Forms: New neutralization and stabilization technologies enable production of high-concentration (60-70%) liquid SDBS, reducing transportation costs and packaging waste by 30%.

4. Application Evolution: From Traditional Cleaning to Specialized Markets

Household Detergents: Continues as the primary component in powder and liquid laundry detergents, dishwasher formulas, and hard surface cleaners, particularly in emerging markets.

Industrial Applications: Used in textile processing, metal cleaning, emulsion polymerization, and enhanced oil recovery, where its cost-performance ratio remains unbeatable.

Agricultural Adjuvants: Serves as a key component in pesticide and herbicide formulations, improving spreading and absorption on plant surfaces.

Personal Care: Incorporated into economical shampoos, body washes, and hand soaps, often blended with milder surfactants to balance performance and mildness.

Niche Applications: Emerging uses in concrete admixtures, fire-fighting foams, and petroleum recovery demonstrate the continued versatility of this classic surfactant.

5. Future Outlook: Balancing Economics with Environmental Responsibility

Growth Drivers:

Emerging Market Demand: Population growth and rising hygiene standards in Asia-Pacific, Africa, and Latin America continue to drive volume growth.

Performance Economics: Unmatched cost-effectiveness ensures SDBS remains essential for manufacturers targeting price-conscious consumers.

Technical Innovation: Continuous process improvements and formulation optimizations address environmental concerns while maintaining competitive advantages.

Market Challenges:

Environmental Regulations: Increasing restrictions on surfactant discharge in wastewater, particularly in Europe and North America, pressure formulators to consider alternatives.

Bio-based Competition: Growing market share of alkyl polyglucosides, sophorolipids, and other bio-surfactants in premium product segments.

Feedstock Volatility: Dependence on petrochemical-derived benzene and LAB subjects producers to raw material price fluctuations.

Consumer Perception: Growing consumer preference for "green" and "natural" products influences purchasing decisions in developed markets.

Industry Insight: The SDBS market exemplifies the complex balance between established chemical technologies and evolving sustainability demands. While facing undeniable pressures from environmental regulations and premium alternatives, SDBS maintains fundamental advantages in cost and proven performance that ensure its continued dominance in global cleaning markets for the foreseeable future. The strategic future for producers lies in optimizing environmental performance through advanced manufacturing technologies, developing specialized formulations for industrial applications less sensitive to "green" marketing, and strategically positioning SDBS as part of blended surfactant systems that balance performance, cost, and environmental impact. Successful companies will be those that leverage SDBS's economic advantages while innovating to meet the sustainability standards of tomorrow's markets.